Delivering dynamic training courses designed to empower individuals and organizations with essential skills for success in today's competitive landscape

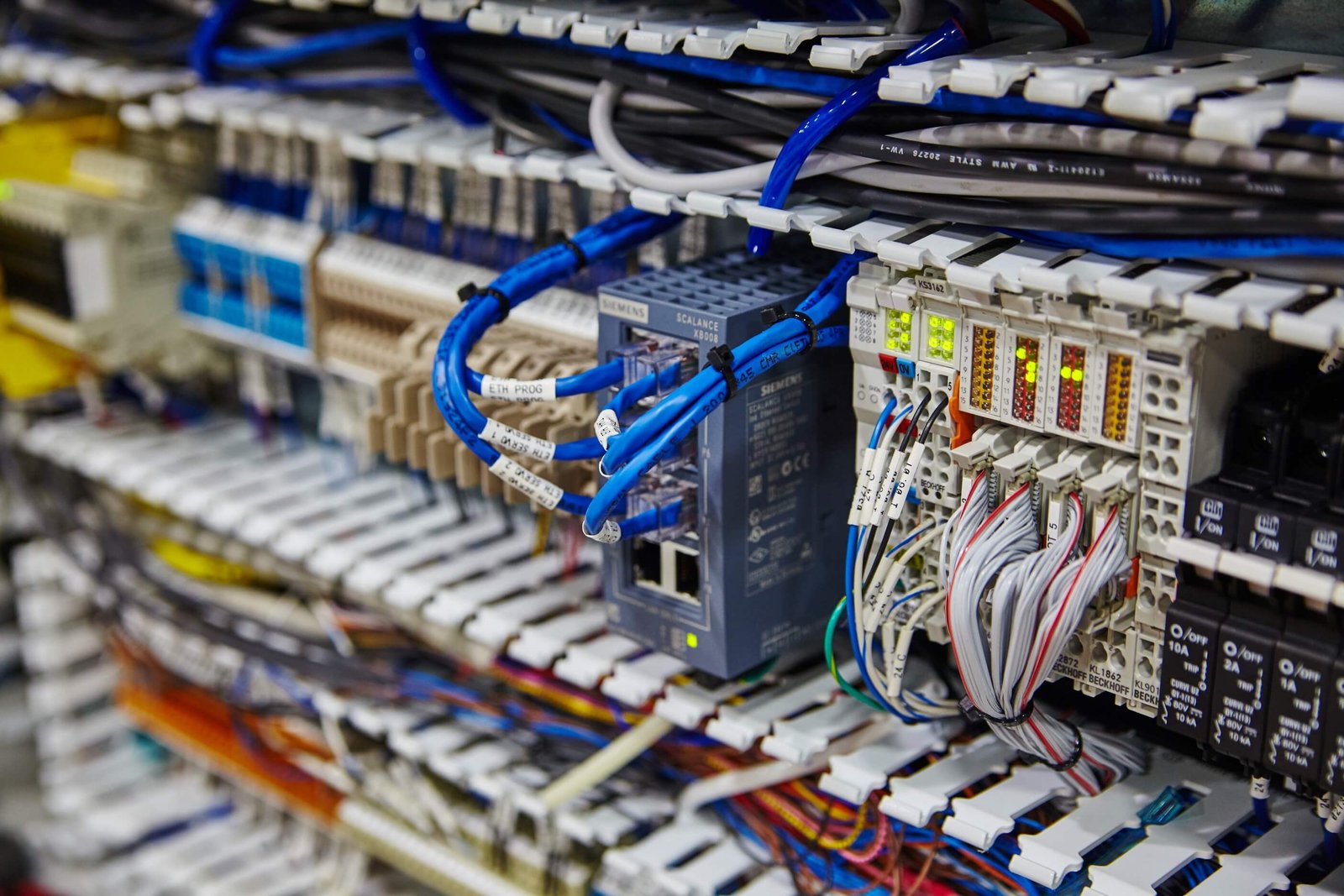

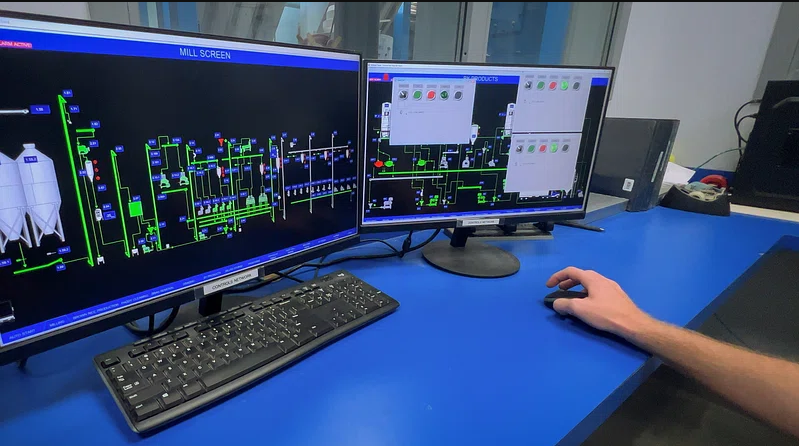

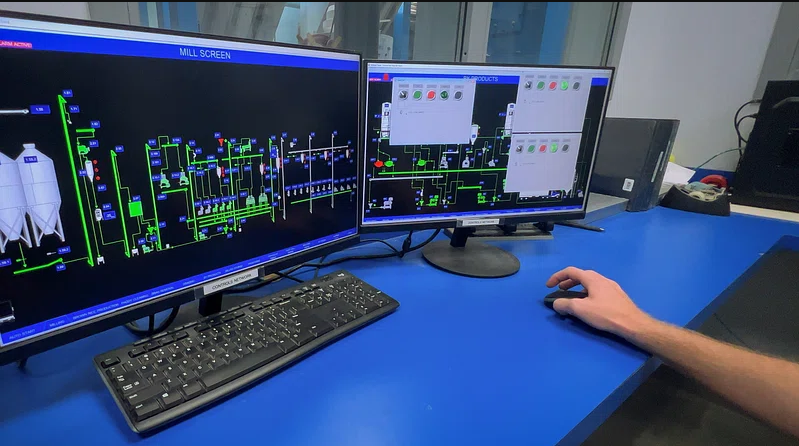

This course on PLC fundamentals covers essential concepts such as hardware integration and interfacing with input/output devices. It introduces IEC 61131-3 programming languages, including loops, cases, timers, and counters for automation logic. Remote access and alarm management are also addressed for enhanced system control. The course further explores PLC-HMI interfaces, web-based HMI with cloud integration, and SCADA systems, emphasizing user access control and security. Integration of PLC and SCADA systems is explained alongside power measurements and monitoring, ensuring a comprehensive understanding of modern industrial automation.

SCADA (Supervisory Control and Data Acquisition) systems are vital for monitoring and controlling industrial processes. PLC (Programmable Logic Controllers) manage real-time automation tasks, while HMIs (Human-Machine Interfaces) provide intuitive user interfaces for system interaction. Web-based HMIs extend control capabilities to remote users, enabling cloud-based monitoring and control. SCADA systems offer customizable user access and privileges, ensuring secure operations. Integration of PLCs with SCADA systems enhance real-time data acquisition and control. Power measurements and monitoring within SCADA provide critical insights into energy consumption and efficiency, optimizing overall system performance.

Data communication protocols facilitate seamless communication between industrial devices and systems. Modbus-RTU and ProfiBus are widely used serial protocols for efficient data transfer in automation environments. BACnet-MSTP and KNX are essential for building automation, enabling device communication over twisted-pair wiring. Modbus-TCP and ProfiNet extend communication capabilities to Ethernet-based networks, providing faster and more flexible data exchange. BACnet-IP and KNX-IP further enhance building automation by allowing integration with IP-based networks for remote monitoring and control of connected systems.

Lighting control systems are crucial for optimizing energy use and enhancing lighting flexibility in various settings. Panelboards distribute power to lighting circuits, providing centralized control. Dimming controls allow for adjustable light levels, creating customized environments while saving energy. Addressable controls offer advanced lighting management by enabling individual fixture control for precise lighting schemes. Relay-based systems are reliable for switching large loads, offering simple on/off control for multiple circuits. Together, these technologies ensure efficient, flexible, and scalable lighting solutions across different environments.

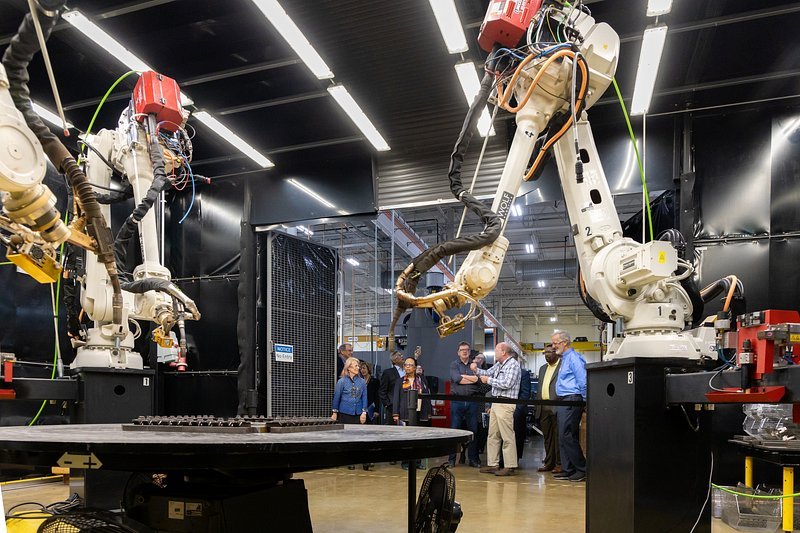

Modern motion control systems utilize advanced technologies such as inverters, servos, and stepper motors to achieve precise movement in industrial applications. Inverters control motor speed and torque, while servos provide accurate positioning and motion control. Stepper motors offer reliable and incremental movement for various automation tasks. This course equips technicians with the essential knowledge to maintain, troubleshoot, and optimize motion control systems. With hands-on training, participants will learn to ensure smooth and efficient operation of these systems in industrial environments.

Portable Training Kit With BECKHOOF CX7000

Lorem ipsum dolor, sit amet consectetur adipisicing elit. Cum porro eum consectetur impedit sint voluptatum odit ullam dolore hic natus dicta quis aliquid placeat nemo, deleniti officia ipsum vero sequi.

Order NowPortable PLC Training Kit Bodys

Lorem ipsum dolor, sit amet consectetur adipisicing elit. Cum porro eum consectetur impedit sint voluptatum odit ullam dolore hic natus dicta quis aliquid placeat nemo, deleniti officia ipsum vero sequi.

Order Now